Top-Rated Water Line Repair Company

Looking for reliable Lawrenceville water line repair pros? We implement cutting-edge technology to identify water pressure concerns, water leaks, and quality problems through pressure mapping, precision detection methods, and pipe cameras. You'll be provided regulation-compliant repairs using AWWA/ASTM protocols, NSF-61 supplies, appropriate bedding/compaction, thrust restraint, and confirmed disinfection. We handle paperwork, 811 locates, PRVs/backflow compliance, and document pressures, tests, and warranties. Using either trenchless or open-cut approaches, we coordinate materials to red clay soils and local pressure zones for durable results. Discover how we protect your home and restore service effectively.

Critical Highlights

- Licensed Lawrenceville experts who adhere to Georgia, Gwinnett County, and City regulations, complete with permits, 811 locates, and AWWA/ASTM-compliant materials

- Fast emergency service supported with written scopes, itemized pricing, quality assurance, and visually documented change orders.

- Proficient in diagnostic techniques: thermal imaging, pressure mapping, acoustic leak detection, and video inspection for precise problem identification.

- Provide trenchless and open-cut repair solutions, featuring proper bedding, thrust restraint, pressure testing, and disinfection meeting AWWA standards.

- Guide property owners on leak signs and provide detailed test reports, chlorine residuals, and final restoration verification.

Key Indicators Your Lawrenceville Home's Water Line Requires Repair

Identify issues at the onset to stop expensive damage and code violations. Look out for lower flow across various taps, continuous low pressure when valves are entirely open, or sudden jumps on your water bill. Check for moist drywall, slab warmth, water pooling in the yard, or meter movement with all fixtures off. Monitor leaky fixtures that continue after cartridge replacement, as they may indicate upstream supply issues. Be alert to hissing at shutoffs, shaking in pipes, or ongoing filling at the toilet.

Watch out for signs like discoloration, sputtering taps, or strange smells that point to contamination or system intrusion. Inspect the service line entry point for mineral buildup, leaks, or corrosion. Test the functionality and marking of shutoff valves. If you detect any of these code-relevant conditions, isolate the line and schedule a licensed assessment.

Common Causes of Water Line Issues and Pressure Problems

You'll discover drops in pressure and water leaks when aging or corroded pipes reach end-of-life, particularly with non-code-compliant materials. Ground movement and invasive tree roots can damage connections, compress piping, or misalign fittings, creating breaks and backflow risks. Excessive system pressure and freeze-thaw cycles weaken pipes and connection points, so it's essential to service a PRV and proper insulation to stay compliant and safe.

Aging or Corroded Plumbing

Although a system meets code at installation, worn and oxidized pipes turn into a primary source of leaks, line breaks, and pressure loss. There are issues with mineral buildup, corrosion damage, and metal deterioration that degrade pipe integrity and create leak points. Galvanized steel and older copper can blister, while cast iron oxidizes, thereby raising breakdown potential and water quality issues. If you still have lead plumbing or brass components containing lead, deterioration may release particles and elevate lead contamination, triggering health and code concerns.

Make sure to track pressure variations, color changes, and small leaks. Execute ultrasonic thickness testing, corrosion coupon analysis, and water chemistry profiling. Switch out affected areas with authorized materials, install dielectric unions, regulate pH/alkalinity, and put in place corrosion control following approved protocols.

Soil Changes and Root Systems

When soils move, settle, or shift from moisture-related cycles, construction activity, or freeze-thaw cycles, underground water lines become unevenly supported and develop connection stress and bends. You'll observe poor positioning and joint displacement that result in water loss and pressure drops. Foundation settlement can fracture rigid piping or compromise mechanical connections, specifically at supply tees and pipe intersections.

Root systems infiltrate tiny cracks and joint spaces, with root intrusion accelerating when moisture is detected. As root systems develop, they force connections apart, impede water flow, and overload thrust areas. Prevent issues by ensuring adequate coverage, installing appropriate bedding, proper compaction, and joint supports. Take precautions by using root-resistant species, protective barriers, and periodic inspections with leak detection to identify issues early.

Freezing Under Pressure

While distribution networks are built for a specified maximum working pressure, pressure surges from rapid valve shutoffs, pump operations, or fire suppression needs can surpass limits and create pressure surges (water hammer) that damage pipes, compromise gaskets, and stress joints. You'll see a high pressure surge move at valve speed, rebounding at dead ends and appurtenances, concentrating force at tees, bends, and couplings. To mitigate this, put in place ASSE-listed pressure-reducing valves, air/vacuum release valves, and slow-closing, full-port valves per local code. Maintain anchor blocks and thrust restraint.

Cold weather periods trigger freeze expansion in inactive or under-insulated water lines. The volumetric expansion of water by 9% risks breaking CPVC, copper, or PEX plumbing parts and compromise meters. You can avoid these issues with regulation-depth burial depth, sufficient insulation, heat tracing, and controlled drip to reduce pressure buildup.

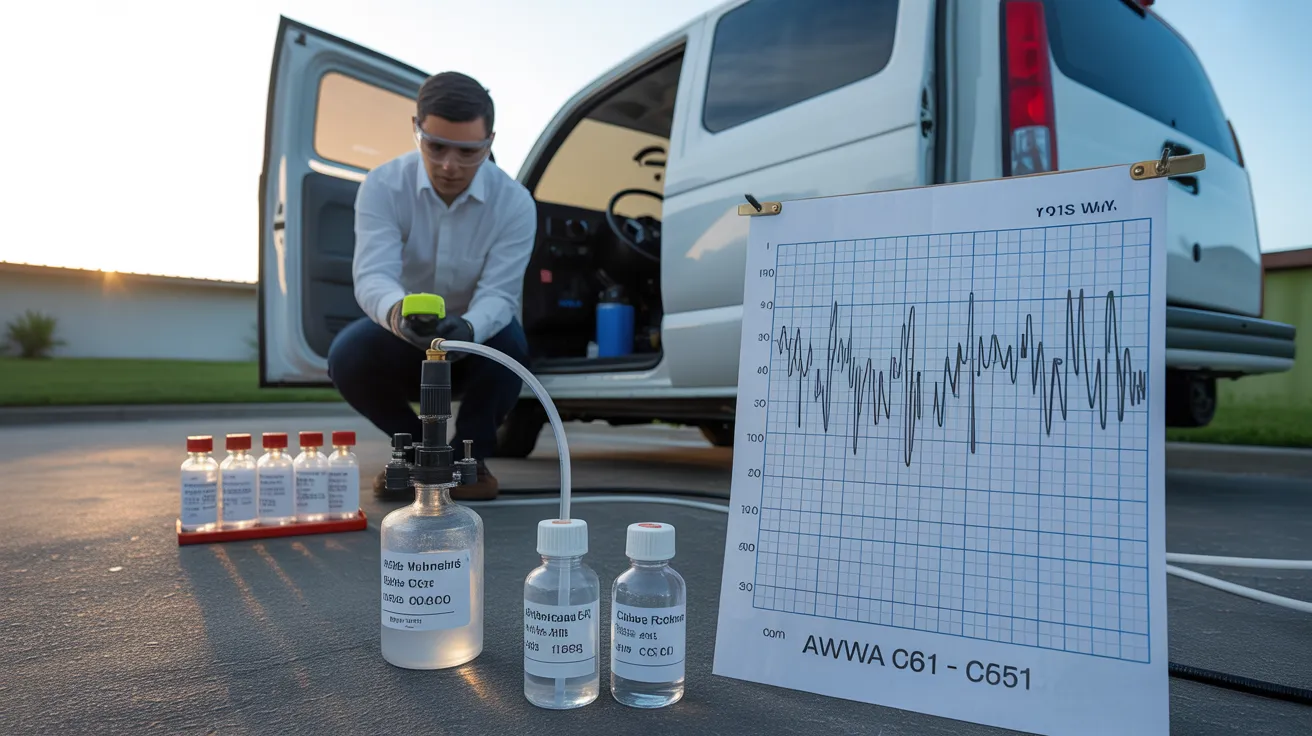

Our Systematic Water Line Diagnostic Method

Starting with a systematic approach to narrow the problem methodically: we initially checking pressure levels at reachable outlets, then separate system sections to verify whether the problem is related to main lines, branches, or specific fixtures. Our team will evaluate results against building code requirements, document variances, and maintain backflow safety. Subsequently, we perform pressure mapping from meter to terminal points, documenting drops that indicate obstruction or leaks. We use acoustic correlation to find subsurface anomalies and thermal imaging to detect masked water damage or temperature differences around slabs and walls. We inspect PRVs, shutoffs, and expansion controls, confirming alignment and performance. In conclusion, we assess material continuity, bonding, and depth-of-cover where exposed, identify service lines, and provide a clear, code-aligned evaluation you can examine and approve safely.

Service Solutions We Rely On for Long-Term Success

We focus on proper construction, safety measures, and lasting durability: we establish repair methods based on material specifications, diameter measurements, depth factors, and code compliance, then implement with AWWA- and IPC-compliant procedures. You receive detailed material specifications, NSF-61 certified materials, and joints assembled to manufacturer torque specifications. We execute pressure validation to AWWA C600/C605 standards, perform durability testing on connections and restraints, and perform sanitization per AWWA C651.

When working with galvanized or corroded steel, we section off areas, fit dielectric unions and upsize components to minimize friction loss. For copper installations, we utilize brazing techniques or lead-free press fittings with protective sleeving. In PVC/HDPE installations, we apply solvent-welding or thermal fusion techniques using precision beads and add thrust blocks at crucial bends. Our process includes adding tracer wire, install ASTM-compliant pipe bedding, backfill using compacted lifts, and confirm system operation through comprehensive flow, pressure, and leak testing before project completion.

Trenchless vs. Traditional Water Line Repair

Sort through the possibilities by coordinating method to property restrictions, pipe type, and code. In cases where the service line is copper, HDPE, or PVC with confined access and stable ground, trenchless pipe renewal - pipe bursting or cured-in-place lining - offers limited disturbance, preserves landscaping, and complies with ASTM/ICC standards when implemented to manufacturer specs. Confirm utility locates, backflow protection, and pressure ratings. For severe offsets, broken portions, undersized lines, or galvanized/lead pipe replacement, go with traditional open-cut. It allows full inspection, suitable foundation, correct slope, thrust restraint, and code-compliant materials.

Check soil depth, groundwater levels, and distance to structural elements. Secure required permits and inspection points. Perform pressure tests, sanitize as per AWWA guidelines, and restore ground cover with carefully compacted backfill. Use traffic safety measures, proper shoring, and personal protective equipment. This will lower potential risks, ensure system integrity, and comply with Lawrenceville standards.

Transparent Pricing and What to Expect During Service

Before we begin, you'll receive a comprehensive scope, itemized cost breakdown, and a maximum cost aligned with project requirements and site parameters. We outline client requirements up front: comprehensive estimates include materials, labor, permits, utility locating, traffic control, and restoration. You'll sign off on any alternates-whether trenchless or traditional-before work begins.

When we arrive, we check shutoffs, identify utilities per 811, and implement PPE and site controls. We carefully evaluate pipe specifications, material, depth, and serviceability, before proceeding with the planned repair. Should we discover varying concealed conditions, we stop work, share photo documentation, and issue a change order for your authorization-keeping you informed.

You'll observe daily progress notes, pressure and disinfection results when applicable, and a clean site. The final invoice corresponds to the approved scope, with warranties provided in writing.

Regular Inspections to Safeguard Your Plumbing

Even if your water line appears to function properly under regular usage, scheduled assessments detect small problems before they become costly leaks, utility disruptions, or property issues. During our professional assessment, we carefully examine both static and dynamic pressure measurements, inspect backflow prevention devices, and log meter measurements. We utilize state-of-the-art tools including acoustic listening, thermal scanning, and video pipe inspection to detect microscopic leaks, pipe deterioration, root invasion, and misaligned connections without unnecessary digging.

We additionally confirm code compliance: proper burial depth, approved materials, tracer wire on PE services, and accessible shutoff valves. Seasonal maintenance is crucial - freeze-thaw cycles, peak summer demand, and ground movement can stress connections and saddles. Through comprehensive homeowner education, you'll recognize when to notify us about low pressure, water clarity issues, or soggy soil. Maintenance is performed quickly in accordance with ASTM and IPC/UPC standards, ensuring water safety and structural stability.

Understanding Why Local Knowledge is Essential for Lawrenceville Properties

You should work with a contractor who understands Lawrenceville's soils and chooses pipe materials to avoid corrosion, heaving, and premature failure. Local pros align your project with Gwinnett County regulations, licensing, and inspection requirements to prevent compliance issues and corrections. When a line breaks, they are familiar with the streets, shutoff locations, and utility contacts, so you get rapid, protected emergency service.

Pipe and Soil Compatibility

Given that Lawrenceville's challenging soil conditions and varying moisture levels place specific pressures on buried utilities, utility pipe choices and placement must match local geotechnical conditions to stay code-compliant and durable. It's essential to have materials and methods proven compatible with soil compatibility, groundwater fluctuations, and shrink-swell cycles. Experienced local professionals recommend HDPE, PVC, or ductile iron with suitable SDR ratings, anti-corrosion measures, and reinforced joints to manage ground movement.

They'll assess the soil gradation, then create pipe bedding with well-graded angular material to provide uniform haunch support, shield connection points, and prevent point loading. Proper trench width, lift thickness, and compaction density reduce movement and subsidence. Where aggressive clay exists, they'll install protective wrapping, cathodic systems, or isolation joints. Precise backfill moisture control and sequential compaction preserve alignment and increase longevity.

Code Compliance Requirements

Each regulatory level - from Lawrenceville municipal codes to regional and state-level plumbing standards - regulates water service installation requirements and inspections. You need a contractor who thoroughly understands both local amendments and base IPC requirements, understands separation distances from utility lines and systems, and selects AWWA-compliant materials certified for area-specific pressure levels. They'll calculate frost line depth and vehicle load requirements, add necessary backflow preventers, and ensure proper electrical bonding of metal components.

Local knowledge streamlines permit timelines by submitting certified site layouts, utility locates, and tap permits in the sequence inspectors expect. A verified inspection protocol includes trench protection, foundation and backfill, thrust restraint, service capacity, pressure testing and leak checks, valve positioning, shutoff valve accessibility, meter installation, and sanitization confirmation prior to site repair.

Faster Emergency Response

An expert who knows Lawrenceville's pressure systems and utility specifications typically delivers the fastest solution. When there's a pipe burst, you need immediate response, not uncertainty. Professional technicians will readily identify your meter, confirm service line materials, and locate leaks using their expertise with district valves, limiting shutdown impact and potential damage. Implementing strategic procedures, they organize steps: properly control water flow, protect against electrical hazards, and regulate pressure according to UPC/IPC requirements.

They also streamline 811 coordination, interpret municipal cutoff protocols, and obtain right-of-way access without delays. Professionals show up with the appropriate CTS, copper, or HDPE fittings and validated backflow protection, eliminating noncompliant repairs. They monitor pressures, chlorine residuals, and bacteriological standards, execute controlled repressurization, and rapidly reinstate operations while ensuring safety or code.

Popular Questions

Are You Available for Immediate Same-Day Water Line Fixing in Lawrenceville?

Yes, you can urgent same-day water line repair in Lawrenceville. You'll get 24/7 support, rapid assessment, and code-compliant remediation. We isolate the leak, disable utilities, and conduct pressure testing, line tracking, and camera inspection to pinpoint failures. Our specialists perform trenchless or open-cut repairs per local code, employ approved fittings, and reinstate service with documented pressure and contamination tests. You'll get clear pricing, safety controls, and follow-up monitoring to prevent recurrence.

Are Your Technicians Licensed, Insured, and Background-Checked?

Yes - every team member is completely certified, insured, and background-verified. Curious how we guarantee trust? We validate licensing requirements, confirm insurance policies, and perform detailed background investigations before authorizing service calls. You can expect code-compliant service, priority safety protocols, and verification of qualifications when needed. We also insist on ongoing training, adherence to local and national plumbing codes, and jobsite safety protocols. You'll experience clean ID, clear estimates, and professional conduct from arrival to final inspection.

What Coverage is Available for Parts and Labor Warranties

You get a comprehensive warranty package: parts follow applicable Manufacturer warranties, and labor is covered with clear Labor guarantees. Components usually include 1-5 years per manufacturer specifications; registration is completed when required. Labor is guaranteed for 12 months, following IPC/UPC code and local amendments. We thoroughly document pressure tests, depth/bedding, and backfill in accordance with safety standards. The warranty doesn't cover read more misuse, third‑party damage, and freeze events. You'll get complete details about claim procedures, response timelines, and transferability terms.

Do You Manage Permits With the City of Lawrenceville?

Indeed, it's possible to arrange permitting with the City of Lawrenceville. You'll initiate permit assistance by delivering a detailed scope, site plan, and utility locates. You'll handle city coordination by booking inspections, adhering to Gwinnett County/Lawrenceville codes, and securing right-of-way approvals when trenching streets. You'll verify backflow, depth-of-cover, and material requirements (e.g., Type K copper/CTS PE). You must follow traffic control per MUTCD, record as-builts, and finalize permits only after final inspection approval.

What Payment Plans Do You Provide for Extensive Repairs?

We provide Flexible Financing and Deferred Payment options for major repair work. You can select structured plans that meet building code requirements, product specifications, and safety protocols. We thoroughly verify cost projections, permits, and inspection protocols, then align payment terms to your financial needs. Payment plans offer low-interest terms, interest-free periods, and milestone-based disbursements linked to project milestones. Applications are fast, obtain swift responses, and complete paperwork electronically. We won't compromise on workmanship, safety measures, or warranty terms to fit payment plans.

Wrapping Up

It's not a coincidence you've discovered pressure issues at the same time a depression formed in your neighbor's yard. You likely share an old utility connection. We offer regulation-adherent diagnostics, pressure testing, and leak location services that prioritize security and land preservation. Our experts will locate service disconnects, confirm backflow protection, and choose optimal repair solutions according to area requirements. You'll receive clear pricing, handled permits, and site cleanup. Reach out immediately before a small problem escalates to a serious cross-connection or structural risk.